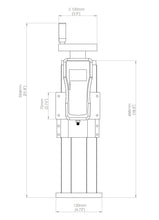

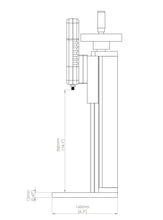

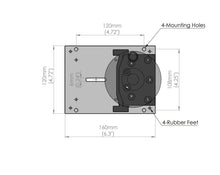

MTS5-300 is a ball screw & ball nut driven, hand wheel operated, force test stand. Choose from a stand-only option or fully assembled with a DFS model force gauge. Maximum stroke length is 11.8 in / 300 mm.

- The rated load for the test stand is up to 1000 N (220 lbf / 100 kgf). The maximum Tension/Compression load is 1200 N(264 lbf / 120 kgf)

- CNC grade 16 mm ball screw and ball nut for smooth and precision positioning

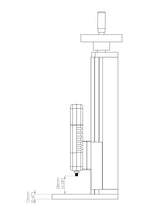

- Test stand works in tension or compression mode

- Solid stainless steel, serrated hand wheel

- Included seven pieces of stainless steel accessories set, two gauge mounting plate and screws. (grips and clamps are not included)

- The gauge works in Peak Hold, Track, Tension and Compression modes

- A factory-issued calibration certificate is included for the force gauge

The test stand provides precise force control with a 5 mm displacement for each handwheel turn. To apply the maximum force, only lightweight (small torque) is required on the handwheel due to the friction-free ball nut ball screw system. The load mounting plate at the bottom has a 6 mm slot for easy mounting of a grip or clamp.

For detailed information on DFS gauge, please see the DFS Series product page.

Remark: The feedback when applying tension or compression can be felt due to the low friction. When testing an elastic spring material, the handwheel may turn by itself as the material returns to its original shape after removing your hand from the handwheel.